With pixel-level detection accuracy, it supports PDF file modeling and can be used for quality inspection in pre-press stage, defects sampling and color variation detection. This product is cost-effective because it is more accurate than manual inspection and can be connected to several presses at the same time which will save labor costs to a great extent.

Based on the experience of adding nearly 100 inline inspection systems on banknote printing machines, we advocate the concept of printing process quality control to improve product quality and reduce waste. Through analysis of printing defect data, it provides quality improvement suggestions and helps to enhance the efficiency of enterprises.

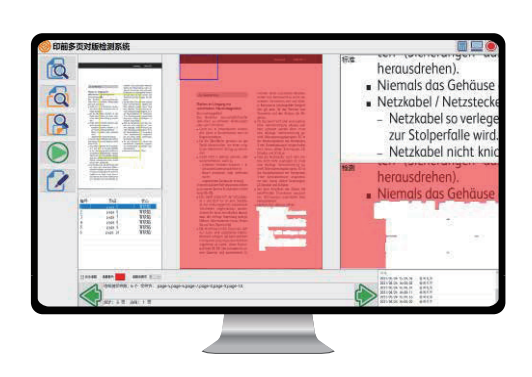

This system compares the PDF template with the sample sheet to detect the plate defects and printing defects before starting the printing work. It helps label enterprises to control the product quality and prevent whole roll waste which is cost effective.

Suitable for the pre-press department and gravure plate making enterprises.

Based on the successful development and application of Large-Format Banknote Quality Inspection Machine, the platform and system of this machine own completely independent intellectual property rights. It can sort the good sheets and rejecting sheets into different bins.

It is mainly used for the final inspection of printed products after cutting in the packaging industry such as medicine packs, cigarette packs, and daily chemicals.